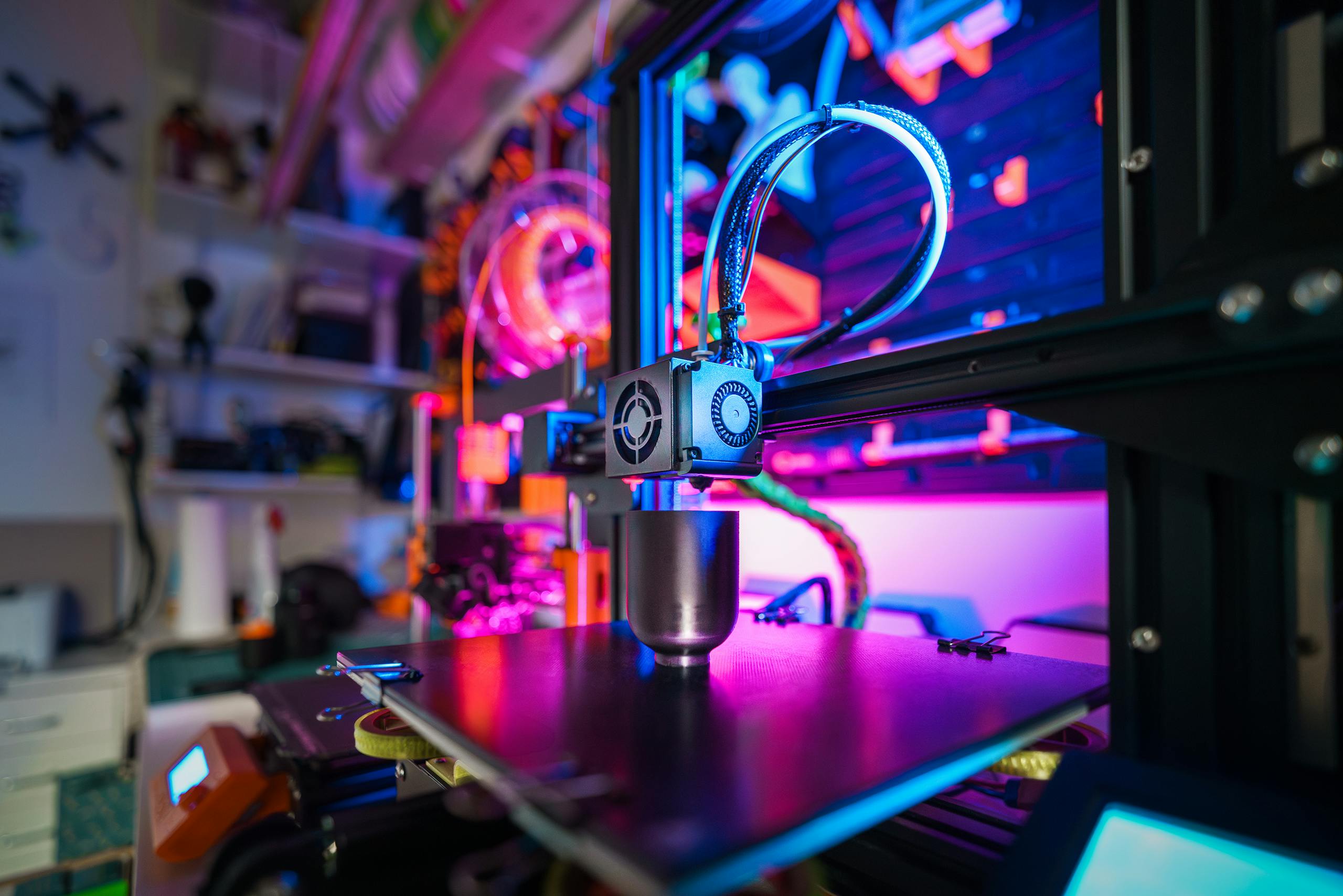

Top 10 Best 3D Printers for Beginners and Professionals

This year 3D printing has made huge strides, with many exciting models to choose from. To save you time, we’ve selected and rated our top picks, based on performance, features, reviews and price. No matter if you’re just getting into 3D printing or have some experience under your belt, this selection offers a variety of great options for different purposes.

Creality K1C 3D Printer, 2024 New Version 600mm/s Fast Printing Speed

- The Creality K1C prints at a fast 600mm/s with 20000mm/s² acceleration, making it 12 times quicker than regular 3D printers.

- It's fully assembled and ready to use within 3 minutes, with auto Z offset, auto leveling, and input shaping features for easy setup.

- The clog-free direct extruder supports a range of filaments, including carbon fiber, with a durable nozzle that can handle high-temperature printing.

- AI Lidar and a smart camera monitor prints in real-time, detecting any issues and stopping the job when necessary.

- Its upgraded cooling system includes multiple fans to prevent heat creep, reduce stringing, and improve the overall print quality.

Creality K1 SE 3D Printer, 2024 New Version 600mm/s High-Speed Hands-Free

- The K1 SE 3D printer is 12 times faster than standard models, reaching speeds of 600mm/s and acceleration of 20000mm/s² thanks to its CoreXY system.

- Its flagship extruder features a side spring and ball plunger for precise filament feeding, supporting both regular filaments and flexible TPU.

- Equipped with a tri-metal nozzle and 60W hotend, the printer delivers high-quality prints and allows for easy maintenance and quick nozzle swaps.

- The sturdy die-cast aluminum frame with corner gussets and crossbeams ensures stable operation by reducing vibrations.

- One-tap auto-calibration and anti-vibration fan technology, combined with Creality OS and Creality Cloud, offer users an advanced and easy printing experience.

Creality K1C 3D Printer, 2024 New Version 600mm/s High-Speed Auto Leveling

- The K1C 3D Printer is built with a CoreXY system, enabling it to reach speeds of up to 600mm/s and 20000mm/s² acceleration, making it 12 times faster than regular 3D printers.

- It features a clog-free direct extruder and a tri-metal "Unicorn" nozzle, allowing for easy printing of carbon fiber filaments and quick nozzle swaps.

- The printer offers hands-free auto calibration leveling and dynamic balancing to reduce vibration, ensuring optimal print quality.

- Equipped with an AI camera, the K1C monitors the printing process for foreign objects or malfunctions, enabling real-time monitoring and time-lapse photography functions.

- With support for carbon fiber reinforced filaments, an air purification system, and a silent mode option, the K1C provides a complete 3D printing solution with Creality OS and a powerful software ecosystem.

FLASHFORGE Adventurer 5M 3D Printer with Fully Auto Leveling

- The Adventurer 5M Series offers one-click automatic printing with precise bed leveling, ensuring perfect adhesion and smooth first layers without manual adjustments.

- With a Core XY structure, it achieves ultra-fast printing at 600mm/s and 20000mm/s² acceleration, ideal for rapid prototyping and mass production.

- Quick nozzle changes in 3 seconds, a high-flow 32mm³/s nozzle, and a 35-second warm-up to 200°C make it a smart and efficient option for various creative projects.

- Dual-fan nozzles, vibration compensation, and multiple nozzle sizes ensure superior print quality and adaptability to different materials.

- Real-time monitoring through the Flash Maker mobile app allows users to track progress, adjust parameters, and receive alerts for seamless printing control.

R QIDI TECHNOLOGY X-PLUS3 3D Printers

- The X-Plus3 is a high-performance FFF/FDM 3D printer designed for commercial use, with Klipper firmware and CoreXY structure, reducing print time by 80%.

- It features two nozzle options (copper alloy and hardened steel) and a direct drive extruder, supporting a wide variety of filaments like ABS, PETG, PLA, and more.

- Equipped with an independent chamber heating system that reaches 60°C in 25 minutes, allowing easy, warpless printing of high-performance materials.

- Enhanced hotend cooling, a 9.5:1 gear ratio, and 3x extrusion flow ensure faster, more accurate prints without ringing.

- Lightweight print head and all-metal frame improve resolution, while pressure advance and auto-leveling increase print accuracy.

- Powered by a 64-bit processor (Cortex-A53) with 8G EMMC and 1G DDR3 memory for better performance.

- The X-Plus3 comes fully assembled, suitable for both professionals and beginners, with easy setup and reliable support from R QIDI TECHNOLOGY.

- The QIDI X-MAX3 is a high-speed, large-format 3D printer with a top speed of 600mm/s, 20000mm/s² acceleration, and a print size of 325x325x315mm.

- Equipped with Klipper firmware, a CoreXY structure, and auto-leveling, it comes fully assembled and ready to use out of the box.

- Its ultra-stable all-metal frame, aluminum heatbed, and premium components ensure smooth, stable printing with minimal upkeep.

- The X-MAX3 supports a variety of filaments, including standard materials like PLA and ABS, as well as high-performance options like PA12-CF and PET-CF.

- It features an enclosed chamber heating system, dual cooling fans, Input Shaping, and Pressure Advance for precise, high-speed prints.

- Ideal for projects ranging from detailed prototypes to artistic creations, the printer delivers excellent print quality.

- Open-source Klipper firmware and QIDIslicer software allow for easy remote control and customization of advanced features.

Official Creality Ender 3 V3 Plus 3D Printer

- The Creality Ender 3 V3 Plus offers a large 11.81x11.81x12.99 inch print area, 58% larger than previous models, allowing for bigger or multiple prints at once.

- It supports high-speed printing of up to 600mm/s with 2000mm/s² acceleration and uses dual X and Z axis motors for smoother, more precise movements without belt slips.

- Auto leveling and Z-offset calibration streamline the setup process, saving time and effort before each print.

- The direct drive extruder provides clog-free performance for over 1000 hours, heats up to 300°C in 75 seconds, and supports high-temp filaments like PLA, TPU, and PETG.

- The steel-tipped copper nozzle with a titanium alloy heatbreak ensures smooth extrusion and allows for easy nozzle swapping.

- Featuring dual Y-axis motors, dual Z-axis, and support rods, the printer delivers stable operation, reducing print imperfections like ringing.

- Pre-assembled modules make the printer easy to set up in under 10 minutes, ideal for beginners seeking a reliable 3D printing experience.

Anycubic Kobra 3 Combo 3D Printer

- The Anycubic Kobra 3 supports multi-color printing with 4 colors now and 8 colors coming soon with the Color Engine Hub.

- ANYCUBIC ACE PRO includes Nozzle Clog Detection, Automatic Filament Refill, Drying, and RFID Sync for hassle-free printing.

- It offers high-speed printing at 600mm/s with 20000mm/s² acceleration, 12 times faster than standard FDM printers.

- Vibration Compensation with G-Sensors adjusts motion to prevent ringing and ensure smooth prints.

- Pantone-exclusive color filaments allow for stunning multicolor designs.

- Easy assembly, auto-leveling, and dynamic structure make it user-friendly while offering advanced features.

- The Creality K1C 3D Printer uses a CoreXY system, delivering 12x faster performance with 600mm/s speed and 20000mm/s² acceleration.

- Its direct extruder and tri-metal "Unicorn" nozzle handle high-temperature materials like carbon fiber with clog-free reliability.

- One-tap auto calibration ensures precise bed leveling, while balanced fans reduce print imperfections.

- The AI camera allows real-time monitoring, detecting issues and enabling time-lapse photography.

- Quiet operation (≤45dB) and an air purification system with activated carbon ensure a clean and quiet printing environment.

Creality Ender 3 V3 SE 3D Printer, 250mm/s

- Ender 3 V3 SE prints at 250mm/s with 2500mm/s² acceleration, faster than previous Ender models.

- Assembles in 20 minutes, with auto leveling and Z-offset for easy setup.

- "Sprite" Direct Extruder supports PLA, PETG, and TPU, proven with 500,000+ units shipped.

- Dual Z-axis and steel Y-axis provide stability and reduce wobbling.

- Features a 32-bit silent mainboard and flexible build plate for easy print removal.

- Supports auto filament loading and unloading for quick, effortless filament changes.

Advertising Disclosure: Links on our site may lead to commissions from qualifying purchases, helping us feature the best products.

If you’re just getting into 3D printing, here are a few things to keep in mind. We’ll walk you through the basics of how the technology works, what features to look for, and which materials are best for different projects. This will help you make a more informed decision as you explore 3D printing.

3D Printing Technology

At its core, 3D printing, also known as additive manufacturing, works by creating objects layer by layer. This technology uses different methods such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each process has its unique advantages, depending on the material used, accuracy, and intended application.

For beginners or those who need a reliable workhorse, FDM printers are often the first choice. They tend to be more affordable, user-friendly, and versatile. SLA printers, on the other hand, use resin and are more suited for highly detailed and smooth prints. SLS printers use a laser to sinter powdered material, creating strong and functional parts without the need for supports, making them ideal for industrial applications.

What to Look for When Choosing a 3D Printer

- Purpose of Use

Different 3D printers are designed with specific users in mind. A printer intended for personal or hobbyist use may not be suitable for professional settings. Define your primary use case, such as prototyping, artistic creations, or functional part production. - Build Volume

The size of the printer’s build volume dictates how large the printed objects can be. A larger build volume allows for bigger projects or batch printing but often comes with a higher price tag. Consider your typical print sizes when deciding. - Print Resolution and Speed

Print resolution is measured in microns, and it affects the level of detail in your printed objects. While a finer resolution produces more detailed results, it may increase print times. Speed is another factor; however, faster prints often sacrifice quality. Balance speed and resolution according to your needs. - Material Compatibility

Different 3D printers support various materials. FDM printers can handle a wide range of filaments, including PLA, ABS, PETG, and more. SLA printers use liquid resin, while SLS printers handle powdered materials. Choose a printer compatible with the materials suited for your projects.

Advanced Features in Modern 3D Printers

As technology improves, new features in 3D printers aim to provide better user experiences and higher-quality prints. Some of these innovations include:

- Automatic Bed Leveling

Ensuring the print bed is level is crucial for successful prints. Automatic bed leveling systems help users avoid common issues with first-layer adhesion, which can lead to print failures. - Filament Detection and Resume Printing

Modern 3D printers come equipped with sensors that detect when the filament runs out and can pause the print to allow for refilling. Resume printing functions are also available, allowing the machine to pick up where it left off in the event of a power outage or other interruptions. - Touchscreen Interfaces

Touchscreens provide a more intuitive way to control the printer. Users can easily navigate settings, initiate prints, and monitor progress with just a few taps.

Print Materials

3D printers can handle a wide range of materials, but the type you choose depends on the intended application. Popular materials include:

- PLA (Polylactic Acid): PLA is a biodegradable plastic that is easy to print with and ideal for beginners. It’s best for prototypes, models, and decorative items but lacks the strength of other materials.

- ABS (Acrylonitrile Butadiene Styrene): ABS is more durable and heat-resistant than PLA, making it suitable for functional parts. However, it requires higher printing temperatures and emits fumes, so proper ventilation is needed.

- PETG (Polyethylene Terephthalate Glycol): PETG offers a good balance between flexibility, strength, and ease of printing. It is commonly used for parts that require durability and weather resistance.

- Resins: SLA printers use liquid resins, which produce detailed prints but can be more expensive and require post-processing. There are also specialized resins for industrial or medical applications.

Key Considerations for the Buyers

The 3D printing landscape is always evolving, with new models offering better features, higher precision, and more accessible pricing. For those planning to buy a 3D printer in 2024, here are a few considerations:

- Price vs. Features

While it’s tempting to go for the most feature-rich printer, not all users need advanced features. Consider your needs and budget before opting for a high-end model. A basic FDM printer might be all you need for your projects. - Support and Community

One of the benefits of 3D printing’s popularity is the large community of enthusiasts and professionals available online. Brands that offer excellent customer support and have active communities often make for a smoother user experience, especially when troubleshooting issues or upgrading hardware. - Software Compatibility

Ensure that the 3D printer you select is compatible with popular slicing software like Cura, PrusaSlicer, or proprietary software from the manufacturer. An easy-to-use and regularly updated software platform can significantly improve the printing process.

Environmental Impact and Sustainability

As 3D printing grows in popularity, its environmental impact is an increasing concern. Fortunately, there are ways to minimize waste and make the process more eco-friendly:

- Recycling Filament: Some companies offer filament made from recycled materials, reducing the demand for virgin plastic. You can also recycle your own failed prints or support spools.

- Bio-Based Filaments: PLA is a popular biodegradable material made from renewable resources like corn starch. It’s a greener alternative to traditional plastics but still requires proper disposal to decompose.

- Energy Efficiency: Look for 3D printers with energy-saving modes, and consider turning off the printer when it’s not in use to reduce electricity consumption.

Common Questions About 3D Printers

- Are 3D printers difficult to use?

Entry-level 3D printers are designed to be user-friendly, and many come with pre-configured settings. However, understanding slicing software and maintenance procedures is key to successful printing. - How much maintenance is required for a 3D printer?

Regular maintenance is necessary to keep a 3D printer in good working condition. This includes cleaning the print bed, ensuring nozzles are clear, and updating firmware. Some printers are equipped with automatic calibration features to make this process easier. - How long does it take to 3D print an object?

The time it takes to print an object depends on the complexity, size, and resolution of the model. Small objects may take just a few minutes, while larger, more intricate designs can take several hours or even days.

By selecting a 3D printer that aligns with your specific requirements, you’ll be well-equipped to explore the endless possibilities of 3D printing in the years to come.